In-House Business Operations

1. Production Planning

The extraordinary forecasting and scheduling skills of the people in the production planning department helps FITWELL in determining the production specifications which are formulated to satisfy the expectations and demands of its clients completely.

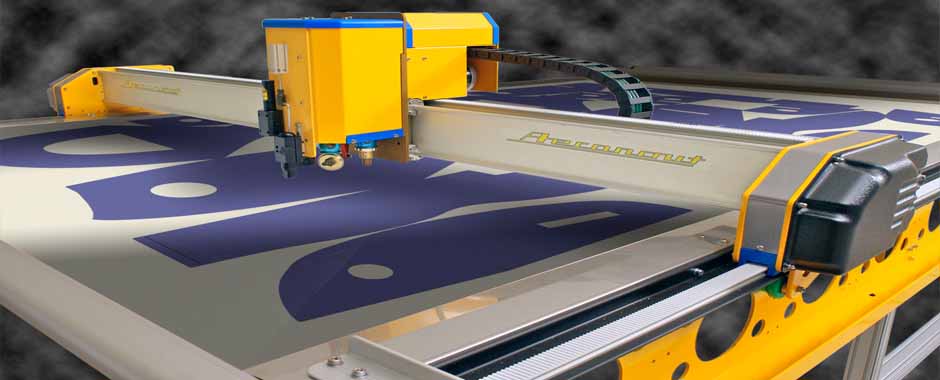

2. Cutting

FITWELL has specifically designed a strategic cutting facility, having 2 Gerber fabric spreaders and 1 Fabric cutter to allow it to meet its clients challenging requirements with ease.

3. Stitching

The stitching stage is extremely significant to ensure that the product takes its final shape according to the requirements of the clients. It is in itself a highly specialized field. The dedicated, trained and skillful workforce guarantees greater concentration and precision in sewing operations, being monitored and controlled at each step by “Quality Managers” according to the predetermined quality standards. The stitching facility is equipped with the following machinery which helps increase production:

- Kaj Machines (Juki / Golden Wheel / Chinki)

- Button Machines (Juki / Golden Wheel / Chinki)

- Over Lock Machines (Brother / Juki): Three Thread, Four Thread, Five Thread

- Stud Button Machines (Automatic Giuzhou (China) / Manual (Local))

- Single Needles Manual (Juki / Golden Wheel / Shingong / Singer / Brother)

- Single Needles Auto (Juki / Golden Wheel)

- Two Needle Machines (Juki / Golden Wheel / Brother / Gepsew)

- Bartack Machines (Juki / Chinki))

- Tape Cutter (Local)

- Blind Stitch Machines (Juki / Treasure / Precious / Tony)

- Chain stitch 12 needle (Kansai / Golden Wheel / Vario-Matic / Siruba)

- Chain stitch 25 needle (Vario-Matic)

- Chain stitch 33 needle (Gepsew)

- Zigzag Machines (Juki)

- Flat Lock Machines (Juki)

- Fusing Machine (Local)

- Metal Detectors (Aolite / Hashima)

A total of 210 machines are set-up in seven lines with 30 machines in each sewing line.

4. Finishing & Packaging

The finishing and packaging facility puts together the apparels after being pressed, ensuring that they go through the strict quality assurance procedures in order to meet the client's exact requirements. These garments are then packaged according to each client's particular instructions.

5. Warehousing

The packed cartons are moved to the company’s warehouse where they are stacked according to the purchase order numbers for being shipped to their destination.